Researchers pioneer production of CAR T-cells using high-density microfluidic bioreactor

Originally published by Singapore-MIT Alliance for Research and Technology on June 27, 2024

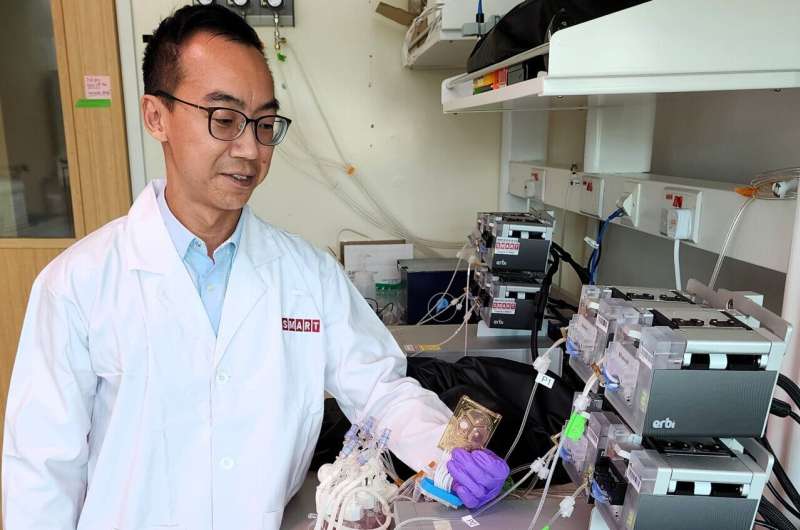

SMART researcher Dr. Wei-Xiang Sin holding the microfluidic chip within which T cells are activated, transduced, and expanded in a 2 milliliter growth chamber. Credit: SMART CAMP

Researchers have developed a novel method capable of producing clinical doses of viable autologous chimeric antigen receptor (CAR) T-cells in a ultra-small automated closed-system microfluidic chip, roughly the size of a pack of cards.

The team from the Critical Analytics for Manufacturing Personalized-Medicine (CAMP) Interdisciplinary Research Group (IRG) at Singapore-MIT Alliance for Research and Technology (SMART), MIT's research enterprise in Singapore, collaborated with researchers from Duke-NUS Medical School (Duke-NUS), Institute of Molecular and Cell Biology (IMCB) at the Agency for Science, Technology and Research (A*STAR), KK Women's & Children's Hospital (KKH) and Singapore General Hospital (SGH).

This method is the first time that a microbioreactor is used in the production of autologous cell therapy products. Specifically, the novel method was successfully used to manufacture and expand CAR-T cells that are as effective as cells produced using existing systems in a smaller footprint and less space, and using fewer seeding cell numbers and cell manufacturing reagents.

This could lead to more efficient and affordable methods of scaling-out autologous cell therapy manufacturing, and could even potentially enable point-of-care manufacturing of CAR T-cells outside of a laboratory setting—such as in hospitals and wards.

Comments

Post a Comment